Corrosion Protection Tapes Market Size, Share, Trends, Growth and Forecast 2030

The corrosion protection tapes market focuses on tapes specifically designed to prevent or minimize corrosion in metal surfaces. These tapes are used across various industries, including oil & gas, automotive, marine, construction, and utilities, to extend the life and maintain the integrity of metal structures and components. Here's an overview of the market:

Market Characteristics

Types of Corrosion Protection Tapes:

- Polyethylene (PE) Tapes: Often used in pipeline coatings due to their durability and resistance to environmental factors.

- Polyvinyl Chloride (PVC) Tapes: Known for their flexibility and resistance to UV light, commonly used in both indoor and outdoor applications.

- Bitumen Tapes: Provide robust protection in harsh environments, often used in underground and underwater applications.

- Wax Tapes: Suitable for irregular surfaces and offer excellent conformability and moisture resistance.

- Butyl Rubber Tapes: Known for their high adhesive strength and resistance to water, chemicals, and temperature variations.

Applications:

- Oil & Gas: Used to protect pipelines, tanks, and other infrastructure from corrosion, especially in harsh and underwater environments.

- Automotive: Applied to protect metal parts and components from rust and corrosion.

- Marine: Essential for protecting metal parts exposed to saltwater, which accelerates corrosion.

- Construction: Used for protecting structural steel and metal components in buildings and infrastructure.

- Utilities: Employed in protecting underground cables and pipes from corrosion.

Market Trends

- Increased Infrastructure Development: The expansion of infrastructure projects, including pipelines, bridges, and buildings, is driving the demand for corrosion protection solutions.

- Growing Awareness of Maintenance and Durability: Industries are increasingly focusing on maintenance and long-term durability of their assets, boosting the demand for effective corrosion protection.

- Advancements in Materials: The development of new materials and technologies for corrosion protection tapes, such as multi-layer systems and enhanced adhesives, is improving the effectiveness and lifespan of these products.

- Environmental Regulations: Stringent environmental regulations and standards are pushing for the use of environmentally friendly and non-toxic corrosion protection materials.

Major Players

- 3M Company: A leading manufacturer of a wide range of industrial tapes, including corrosion protection tapes.

- Nitto Denko Corporation: Offers various industrial tapes, including those for corrosion protection in harsh environments.

- Denso Group Germany: Specializes in corrosion prevention products, including tapes for pipelines and other infrastructure.

- Polyken (Berry Global Inc.): Known for high-quality pipeline coatings and corrosion protection tapes.

- Jining Xunda Pipe Coating Materials Co., Ltd.: A significant player in the pipeline coatings and corrosion protection industry.

Challenges

- High Initial Cost: The initial cost of high-quality corrosion protection tapes can be significant, which may deter some customers, especially in price-sensitive markets.

- Competition from Alternative Solutions: Coatings, paints, and other corrosion protection methods can be alternatives to tapes, posing competition within the market.

- Environmental and Safety Concerns: The need to comply with environmental regulations and ensure safe application methods can present challenges.

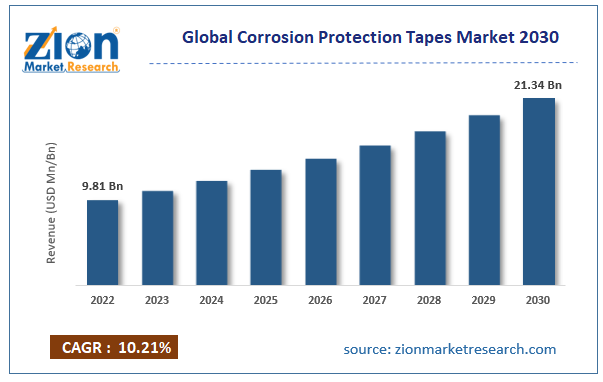

Market Outlook

The corrosion protection tapes market is expected to grow due to the increasing need for asset protection and maintenance across various industries. The rise in infrastructure development projects, particularly in emerging economies, and the focus on extending the life of existing assets are significant drivers. Advancements in materials and technology, along with growing awareness of the importance of corrosion protection, will continue to propel the market. However, addressing cost concerns and environmental considerations will be crucial for sustained market growth.

Comments

Post a Comment