Copper Foil Market Size, Share, Growth Report 2032

The copper foil market involves the production, distribution, and application of thin sheets of copper, typically used in a variety of industrial and technological applications. Copper foil is a critical component in electronics, particularly for printed circuit boards (PCBs), lithium-ion batteries, and electromagnetic shielding. Its high electrical conductivity, corrosion resistance, and mechanical properties make it essential in multiple industries, including electronics, energy, automotive, and telecommunications.

Get a Free Sample : https://www.zionmarketresearch.com/sample/copper-foil-market

Key Applications of Copper Foil:

- Printed Circuit Boards (PCBs): Copper foil is extensively used as a conductive layer in PCBs, essential for electronic devices like smartphones, computers, and home appliances.

- Lithium-Ion Batteries: Copper foil acts as the current collector in lithium-ion batteries, making it crucial for energy storage applications, including electric vehicles (EVs), renewable energy storage systems, and portable electronics.

- Electromagnetic Shielding: Copper foil is also used for shielding electronic components from electromagnetic interference (EMI) and radio-frequency interference (RFI).

- Transformer Windings: Copper foil is utilized in transformers due to its excellent electrical conductivity, replacing traditional copper wire in some applications.

- Other Applications: Copper foil is used in roofing, printing, medical devices, and solar cells, highlighting its versatility in different sectors.

Market Drivers:

- Rising Demand for Consumer Electronics: The rapid growth of consumer electronics, including smartphones, tablets, and wearable devices, is driving demand for copper foil in PCBs.

- Growth of Electric Vehicles (EVs): The transition to electric mobility is accelerating demand for lithium-ion batteries, where copper foil is a key component in battery production.

- Energy Storage Solutions: The global push towards renewable energy and the need for efficient energy storage systems is contributing to the increased demand for copper foil in batteries.

- Technological Advancements: Continuous innovations in electronics and miniaturization of components are driving the need for high-quality, ultra-thin copper foil in advanced PCBs and flexible electronics.

Types of Copper Foil:

- Electrodeposited (ED) Copper Foil: Produced through electroplating, this type of foil is typically used in PCBs due to its higher tensile strength and smooth surface, which makes it suitable for thin and flexible electronics.

- Rolled Annealed (RA) Copper Foil: Manufactured through a rolling process, RA copper foil is more flexible and has better fatigue resistance, making it ideal for high-performance applications like automotive electronics and flexible printed circuits.

- High-Performance Foils: Ultra-thin, high-purity copper foils are developed for specific applications, such as next-generation flexible displays, sensors, and advanced battery technologies.

Market Segments:

- By Application:

- PCBs: The largest application area for copper foil, driven by demand in the consumer electronics, automotive, and industrial sectors.

- Batteries: Copper foil is vital in lithium-ion batteries for electric vehicles and energy storage systems, a rapidly growing segment.

- Electromagnetic Shielding: Used in telecommunications, automotive, and defense industries to protect sensitive electronic equipment.

- By Product Type:

- Ultra-Thin Copper Foil (≤12 µm): Widely used in advanced PCBs, lithium-ion batteries, and flexible electronics.

- Thin Copper Foil (12–35 µm): Commonly used in conventional PCBs and other electronic applications.

- Standard Copper Foil (>35 µm): Utilized in industrial applications like transformers, roofing, and other electrical components.

Market Trends:

- Surge in Electric Vehicle Production: The automotive industry’s shift toward electrification is a key driver, as copper foil is essential in the manufacturing of lithium-ion batteries.

- Increased Adoption of 5G Technology: With the rollout of 5G networks globally, demand for copper foil in advanced PCBs and communication devices is increasing.

- Flexible and Wearable Electronics: The growing market for flexible and wearable electronic devices, such as smartwatches and health-monitoring gadgets, is spurring demand for ultra-thin and high-performance copper foils.

- Sustainability Focus: Manufacturers are developing copper foil recycling processes and environmentally friendly production techniques to address sustainability concerns, particularly in industries like EVs and renewable energy.

Regional Insights:

- Asia-Pacific: The largest market for copper foil, driven by the dominance of consumer electronics and automotive manufacturing in countries like China, Japan, South Korea, and Taiwan. China, in particular, is a major producer and consumer of copper foil, especially for EV batteries and electronics.

- North America: The region sees strong demand for copper foil due to the expanding EV market, advancements in energy storage, and the growing electronics sector.

- Europe: European countries are investing heavily in electric vehicles and renewable energy systems, boosting the need for copper foil in battery manufacturing and energy storage solutions.

- Middle East & Africa: The market is growing, particularly in the energy and telecommunications sectors, though it remains smaller compared to other regions.

Key Players in the Market:

- Furukawa Electric Co., Ltd.

- Mitsui Mining & Smelting Co., Ltd.

- JX Nippon Mining & Metals Corporation

- Arcotech Ltd.

- Lotte Chemical Corporation

- Circuit Foil Luxembourg

- Doosan Corporation

- ILJIN Materials Co., Ltd.

- Shandong Jinbao Electronics Co., Ltd.

- Lingbao Wason Copper Foil Co., Ltd.

Challenges:

- High Production Costs: Manufacturing high-performance, ultra-thin copper foil requires advanced technology and precision, leading to high production costs.

- Supply Chain Disruptions: Copper is a critical material, and disruptions in copper mining or processing can lead to price volatility and supply shortages, affecting the availability of copper foil.

- Environmental Concerns: The mining and refining of copper have environmental impacts, and the industry faces pressure to adopt more sustainable practices and recycling processes.

- Competition from Alternative Materials: In certain applications, alternative materials like aluminum may pose competition to copper, particularly in batteries, though copper remains the preferred choice due to its superior conductivity.

Directly Purchase a copy of the report with TOC :

Future Outlook:

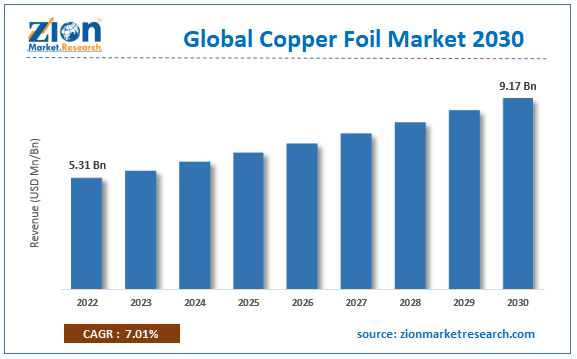

The copper foil market is expected to witness significant growth in the coming years, driven by the rapid expansion of the electric vehicle industry, advancements in energy storage technologies, and the increasing adoption of high-performance electronics. As the demand for thinner, more efficient copper foils increases, manufacturers will continue to innovate in production processes to meet the evolving needs of industries such as electronics, automotive, and renewable energy.

Would you like specific data on market size, growth forecasts, or trends for particular regions or applications?

Contact Us:

Zion Market Research

USA/Canada Toll Free: 1 (855) 465–4651

Newark: 1 (302) 444–0166

Web: https://www.zionmarketresearch.com/

Blog: https://zmrblog.com/

Comments

Post a Comment